CRANE CAM’S GM: COMPANY IS STRONG AND REBOUNDING

Wed, 2011-02-16 14:00

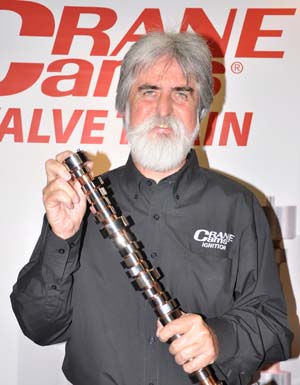

Sean Holly, President and general manager at Crane Cams, wants it known the company is back in business and rebounding strong.

Sean Holly, President and general manager at Crane Cams, wants it known the company is back in business and rebounding strong.

Crane Cams, which is based in Daytona Beach, opened its doors in 1953 and by the late 1960s future drag racing legends like Bill “Grumpy” Jenkins, “Dyno Don” Nicholson, Bruce Larson and Don Schumacher were using Crane camshafts and valve train components in their racing engines.

In the following years, Crane Cams became a respected and iconic brand in the high performance

Sean Holly, President and general manager at Crane Cams, wants it known the company is back in business and rebounding strong.

Crane Cams GM Sean Holly believes the motorsports background of Ken and George Smith is what is fueling the company's rise back to prominence.

“I think customers are going to be very happy and pleased with the new Crane,” Holly said. “These products are made in the United States exclusively by Crane, for Crane customers, and it’s going to be with quality that can’t be beat.”

Crane Cams, which is based in Daytona Beach, opened its doors in 1953 and by the late 1960s future drag racing legends like Bill “Grumpy” Jenkins, “Dyno Don” Nicholson, Bruce Larson and Don Schumacher were using Crane camshafts and valve train components in their racing engines.

In the following years, Crane Cams became a respected and iconic brand in the high performance industry.

However, by February of 2009, the Crane Cams brand encountered difficulties and the company shut its doors. In April of 2009, brothers Ken Smith and George Smith Jr., the owners of S&S Cycle, acquired the Crane Cams assets. S&S Cycle is based in Viola, Wisconsin, and was founded in 1958.

“We took our time to make sure we had the right business plan put together,” said Holly, who is George Smith Jr.’s son-in-law. “Then, we started providing cams in January of 2010 and after updating and acquiring new equipment we have slowly but surely been putting products on the shelf. We started redeveloping our distribution network in March (of 2010), and we started shipping and distribution in April (of 2010) and by December (of 2010) we have been shipping 85 percent complete within a week, and we are shipping globally. We also have re-launched over 2,200 individual products. And, guess what? It is all made in the United States. Our rocker arms are being made by us in Viola, Wisconsin, the lifters are being made by us in Viola, all on modern CNC manufacturing equipment. We have upgraded the product line extensively across the board. The laundry list of what we have done with this line is very hard to get across in a single conversation just because it is huge. For example, there is nobody in the world mak

ing rocker arms the way we are making rocker arms today.”

Holly admitted getting Crane Cams back on track has taken money and time.

“We have absolutely had to invest, but mostly we have invested in trying to upgrade the machining and modernizing the machining,” Holly said. “All this stuff now is being made at S&S Cycle’s 150,000 square foot manufacturing facility in Viola, Wisconsin. We’re making this stuff ourselves and it is high quality. All the hard turn milling and drilling is being done out of Viola now and we’re doing all the finishing work down here in Daytona.”

The hardest thing has been trying to predict when everything is going to be available and manage expectations with the customer base we have. The last thing we want to do is tell somebody it is going to be two weeks (until they get their order), and then be wrong about it. In most instances, we are shipping 85 percent complete within five days. We are able to accomplish this due to our higher levels of inventory that we have invested the last year in producing. - Chase Knight, Crane’s Valve Train product manager

“Ken and George are both racing enthusiasts and they understand the automotive customer very, very well and they know what it takes to make products people want to use,” Holly said. “There are two things I would like to emphasize, those being, that you actually make the products and you actually want to use them. Our products, across the board are pieces we would put in our own vehicles because we know they are the highest quality and best performing pieces that are out there. We know that because we are making them. We’re following a field of dreams type of a model here and we’re ready to make it happen.”

Chase Knight, Crane’s Valve Train product manager, is enthusiastic about Crane’s present and future. Knight has been working at Crane for 43 years.

“I was incredibly thrilled to see Ken and George get Crane,” Knight said. “I knew about the work they did at S&S Cycle and it represented very high quality American-made parts. They (Ken and George) also have a passion for the industry. The S&S Cycle manufacturing facility that we have access to now far exceeds anything the old Crane had. We have had to go through some changes, but they have all been for the positive because the quality has been elevated because of the better machinery that they have.”

Holly said the brass at Crane Cams also knows there’s plenty of room to grow and improve the company.

Knight is enthusiastic about Crane’s present and future. He has been working at Crane for 43 years.

“We have done a lot this last year to 18 months,” Holly said. “The hardest thing has been trying to predict when everything is going to be available and manage expectations with the customer base we have. The last thing we want to do is tell somebody it is going to be two weeks (until they get their order), and then be wrong about it. In most instances, we are shipping 85 percent complete within five days. We are able to accomplish this due to our higher levels of inventory that we have invested the last year in producing. For now, our main focus is to get the existing product line out there, and get people re-comfortable with Crane again and using the Crane product. This is just the beginning. We’re really going to be launching heavily into new product development.”

Knight agreed with Holly.

“We have a lot of new products we want to get on-line and we realize one of the reasons the old Crane failed is because in their last four, five, six years, they hardly had any inventory,” Knight said. “So, if somebody ordered something they would have to wait forever for it. In this industry, you can’t do that. The last 18 months at the new Crane we have spent time and money building a very substantial inventory. So now, if somebody does want something we can ship it in a day or two or three. That’s making all the difference in the world. That makes people realize we’re for real and we can ship, and that our products are higher quality, reliable and beautiful.”

{source}

<div style="float:left; padding:5px;"><script type="text/javascript">

google_ad_client = "pub-8044869477733334";

/* 300x250, created 4/3/09 */

google_ad_slot = "2028912167";

google_ad_width = 300;

google_ad_height = 250;

</script>

<script src="http://pagead2.googlesyndication.com/pagead/show_ads.js" type="text/javascript"></script>

</div><div style="padding:5px;">

<script type="text/javascript">

sr_adspace_id = 2000000613807;

sr_adspace_id = 2000000613807; sr_adspace_width = 300;

sr_adspace_width = 300; sr_adspace_height = 250;

sr_adspace_height = 250; sr_ad_new_window = true;

sr_ad_new_window = true; sr_adspace_type = "graphic";

sr_adspace_type = "graphic";</script>

<script type="text/javascript" src="http://ad.afy11.net/srad.js?azId=2000000613807">

</script></div>

{/source}

Categories: