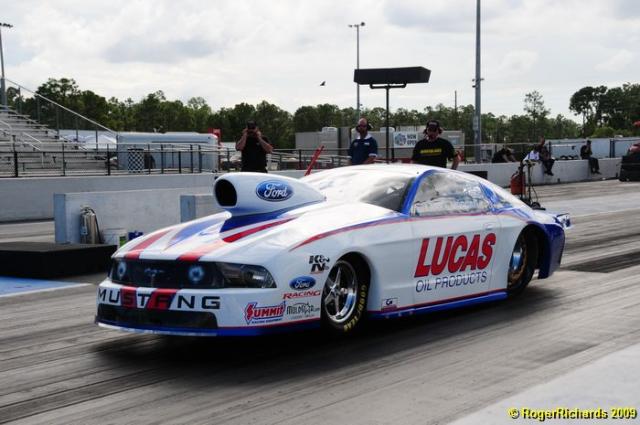

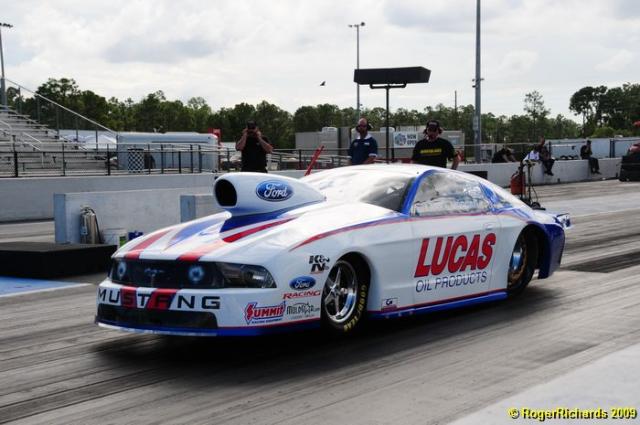

FORD IN PRO STOCK : MELDING THE OLD WITH NEW

Representatives of Ford Motor Company are serious about their increased involvement in NHRA racing, specifically the introduction of the 2010 Ford Mustang into the Pro Stock ranks.

Representatives of Ford Motor Company are serious about their increased involvement in NHRA racing, specifically the introduction of the 2010 Ford Mustang into the Pro Stock ranks.Mose Nowland, Ford Motor Company engine engineer, who has been with Ford since 1955, is happy to report the project is on track and exceeding expectations. Leading Ford back into Pro Stock racing is important to Nowland.

“Well, this project had a little special place for me because it’s something I thought was good for the company, and we hadn’t been doing it,” said Nowland just prior to a recent engine test. “We hadn’t been involved since the Glidden retired, and that was my last involvement.”

Representatives of Ford Motor Company are serious about their increased involvement in NHRA racing, specifically the introduction of the 2010 Ford Mustang into the Pro Stock ranks.

Representatives of Ford Motor Company are serious about their increased involvement in NHRA racing, specifically the introduction of the 2010 Ford Mustang into the Pro Stock ranks.

Mose Nowland, Ford Motor Company engine engineer, who has been with Ford since 1955, is happy to report the project is on track and exceeding expectations. Leading Ford back into Pro Stock racing is important to Nowland.

“Well, this project had a little special place for me because it’s something I thought was good for the company, and we hadn’t been doing it,” said Nowland just prior to a recent engine test. “We hadn’t been involved since the Glidden retired, and that was my last involvement.”

Nowland says he has fielded a lot of questions over the years, the biggest being when Ford might step back into Pro Stock. He wondered the same thing himself.

“Well, it’s never been for me to decide, and I’ve often wondered if we ever would,” Nowland explained. “Under our new management, our venues of racing have changed, and, by golly, Pro Stock has come up again. So, with my desire that I thought it was important to be there, and given the chance to get us there, that’s what [made this special].”

Nowland, with the help of Cunningham Motorsports, has led the way in the development of a new 500 cubic inch Ford engine which will power the Mustangs on the track. The effort is now one-year-old and almost ready for prime time.

The game plan from the start was to meld the old with the new. To use the experience of the past to fast track a completely new engine design into competition.

“Last December we set about designing a new engine for [Pro Stock]. And the engine design was kept simple, a lot of experience and past features went into the engine because we were pretty sure they worked and were reliable. And that’s, I believe, the most important approach that got us there in the shortest time that we’ve spent.” From the start, Ford knew the best route to the finish line was to come out with a “clean sheet” engine. NHRA rules are such that almost anything was possible.

From the start, Ford knew the best route to the finish line was to come out with a “clean sheet” engine. NHRA rules are such that almost anything was possible.

“It was a clean-sheet design challenge,” said Nowland of the effort. “The thing of it is, NHRA really doesn’t have a box that constrains you in the design of the engine. There’s a limit – 500 cubic inch, two valves per cylinder, two four-barrel carburetors, and a 4.900-inch bore spacing – and that’s about what you follow. So, given the experiences of yesteryear of strength, of durability, RPM required for that quarter-mile run, it was just put it together – and with the advantages of compacted graphite iron, we were pretty well assured that we were going to have the strength.”

The combination of experience and a limited number of rules promised to make designing and building a “clean sheet” engine easier that what is typical. Experience was truly the key. The limited number of rules just greased the path. So, was it, in fact, easier building the “clean sheet” engine?

“In most cases it would be a more difficult task because there are a lot more things that you would have to go validate to make sure that you were safe in putting the features in there, but in our particular case, because it was an NHRA Pro Stock engine, we looked around at what our competitors had and made contacts with potential future teams, found teams that were very willing to work with us that had not worked with Ford before, so we had a lot of suggestions from them. I can’t say that the ideas in the complete engine were all mine – I had a lot of good, trustworthy recommendations, and when I researched them, the folks were being very straight with me that they were good features. So, rather than re-invent the wheel and wondering if it will work or not, those are the parameters that we sort of followed.”

Ford has already put two engines to the test with better than expected results at Pomona during the season ending Auto Club Finals.

“The engines came back, and in both cases – we had two cars out there with the Jim Cunningham Motorsports team, one driven by Jim himself and the other by Erica Enders – and both engines came back stronger than when they left, and that’s typical of a race engine. If the engine lives it will generally be stronger by a few horsepower when it gets back. The engines have been torn down, and so far, to date, even through Magnaflux and crack detection, the engines are sound. They are going back together, and, in fact, they’re going out testing with just a fresh set of gaskets in them.”

It was important to get the engines back from Pomona, tear them down and analyze all the parts, according to Nowland.

“The first thing you want to do, in the initial launch of the design in true application, you want to make sure that all the parts and components are in harmony with each other – no fretting material, no metal transfer, fits and finishes are remaining as manufactured, there’s no conflict in the engine that would drain you of horsepower, in other words, high-friction areas and things like that. You look at the performance of the engine on a dynamometer, you look at the performance on the track, and then you disassemble the engine and examine every piece, every moving part, carefully, to see that it is as you designed it and it retained its integrity after that treatment.

“The realistic expectation is that when you look at a used part that has been used within reason and not run short of coolant or oil or anything that, you would like to think that you could put the engine back together with a fresh set of gaskets and that you would have a reasonable number of competition life in that engine.”

To date, Nowland confirms, the engines have met or exceeded expectation. After 50-60 dyno pulls and approximately 14 launches from the starting line all is well. During the off-season the engines will be tested, torn down, examined, rebuilt and tested some more, along with the chassis, which also happen to be new.

“Both teams of our active teams that have engines assembled are doing test trips in the southern, warmer states. I believe one of our teams is testing this December 14th and 15th in the south where the tracks are free of inclement weather; they will test for two days. [Editor’s Note: Two sessions were postponed due to weather and moved to Bradenton, Fla.] And we have to remember that we’re still trying to get acquainted with a brand-new car, because the teams had new chassis built from the ground up to take the installation of the carbon fiber Mustang body. So, they’re brand new from bumper to bumper. Once we get off the test trips, again the engines will get looked at and the chassis will be gone over, every weld will be inspected, every fastener for tightness, and will be under scrutiny and things of that nature.”

Advertisement