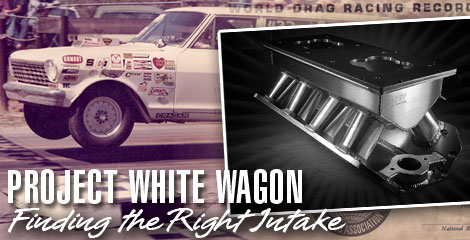

PROJECT WHITE WAGON: SPACE AGE INTAKE MEETS THE BASKET CASE

Gene Fulton remembers the first intake he installed on the small block powering his revered 1964 Chevy II wagon back in 1972.

“It was the first one Edelbrock manufactured,” Fulton proudly proclaims.

Fulton purchased the tunnel ram while he was still in the military, doing a tour of duty in Vietnam. He stored the unit away in his military-issue duffel bag until he returned home.

Fulton had visions of a brighter day when his Air Force days were complete.

A tunnel ram, as he puts it, “was the only way to go racing in Modified back in the day.”

Gene Fulton remembers the first intake he installed on the small block powering his revered 1964 Chevy II wagon back in 1972.

“It was the first one Edelbrock manufactured,” Fulton proudly proclaims.

Fulton purchased the tunnel ram while he was still in the military, doing a tour of duty in Vietnam. He stored the unit away in his military-issue duffel bag until he returned home.

Fulton had visions of a brighter day when his Air Force days were complete.

A tunnel ram, as he puts it, “was the only way to go racing in Modified back in the day.”

That tunnel ram was well ahead of its time. However, today’s tunnel ram makes that original piece look archaic.

Chances are, back then, if Fulton had been given a glimpse of the sheet-metal intake we plan to put on our Project White Wagon, he’d believe it was space age technology. Space age technology so advanced it could only be delivered by little green men wearing silver suits and rocketing through outer space.

Indeed, intake manifold technology compared to the designs in 1971 does appear space age technology.

“The intake manifold design has evolved equally with the cylinder heads in most cases,” said Scott Kieffer, of CFE Racing, a leading intake and cylinder head manufacturer. “The ability of today's racing engines to carry higher engine speeds has made the biggest impact on the design of the manifold. Higher engine speeds require shorter runners and a larger volume in the design of the plenum.”

As our engine development advances in Project White Wagon, you’ll quickly see that this modern day version of the championship relic from the 1970s will be powered by the equivalent of a Pro Stock Truck engine albeit as a 292 cubic inch Chevrolet.

Our Project White Wagon will be classified as a Super Stock/Modified, the equivalent of the old Modified Production class absorbed when Modified eliminator was disbanded after the 1981 season. Modified Production was largely a two four barrel class but those intakes were cast aluminum.

a d v e r t i s e m e n t

Click to visit our sponsor's website

Kieffer has been our point man in developing the cylinder head and intake manifold on our SS/E Modified entry. He’s very familiar with the inner workings of this style of Super Stocker.

“The modified classes of Super Stock allow for more options in parts selection versus the traditional classes of Super Stock which are a bit more restrictive,” explained Kieffer. “When the rules allow for more exotic parts, it gives us more possibilities to develop a more efficient induction system.”

Suffice to say, technology has advanced because of the wide open rules. Because of this the technology attributed to the intake manifold can be as crucial as the cylinder heads in the grand scheme of the race engine.

“If the rules we're dealing with are un-restricted, the manifold design is equal to the importance of the cylinder heads...the manifold is merely an extension of the cylinder head,” explained Kieffer. “A properly designed induction system will feature a manifold that is designed to meet the objectives of the application and complement the heads.”

Project White Wagon will have what industry leaders consider to be the top of the line with the CFE version of the SB2.2 cylinder heads. This sheet-metal intake has been created specifically for our cylinder heads. In the case of the SB2.2, (which is a mirror – port head) it has intake ports which target the center of the engine.

a d v e r t i s e m e n t

Click to visit our sponsor's website

“This allows for some advantages with the use of a single four barrel carburetor but creates some new challenges when running two carburetors so we manipulate the runners in a certain manner to make distribution more equal from cylinder to cylinder,” explained Kieffer. “We design our manifolds around the parameters of the engine and every different type of cylinder head has its own manifold design requirements.”

The deck height on our engine, which will be based off of Dart’s Iron Eagle block, formerly known as the Oldsmobile Rocket block, will be 8.200. This is as about as low of a deck height as you can get.

“The deck height certainly influences the manifold design in the element of plenum area,” explained Kieffer. “As the deck gets taller, the ports are spread farther apart from bank to bank and the plenum gets wider. This can have varying effects on the performance of the engine, but as area of the plenum increases it can create negative effects such as less booster signal and poor fuel distribution in a carburetor application.”

Knowing the ins and outs of intake technology is a trade Foltz has developed and perfected for the last 25 years. The first sheet metal intake manifold that Foltz built was for the Bill Jenkins engine that he also modified the cylinder heads on. Fabricating a manifold turned out to be a more accurate way than welding on the outside of a casting and hand grinding each runner. When you bend and weld the runners together, they are all the same. This allows each cylinder to make closer to the same power levels to one another.

The same holds true today. CNC'ed runners are a step above the fabricated runners when you’re looking for every last bit of horsepower. One piece runners have zero distortion since they are not welded together. Like anything else on a racing engine, the tighter you can hold the tolerances, the more horsepower you can make.

And for us, we’re planning to extract 800 horses from 292 inches of engine. CFE has the technology to make this a realistic projection.

Who’d have ever thunk a junkyard find could yield that?

PART 10, PREPARING THE ULTIMATE BLOCK FROM DART

PAST INSTALLMENTS

* Part 1, Outlining The Project

* Part 2, Getting The Car on The Jig

* Part 3, Preparing for the Four-Link

* Part 4, Preparing the Cylinder Heads

* Part 5, Project Gains A Purpose

* Part 6, Shocking the Wagon

* Part 7, A Real Clutch Player

* Part 8, Nova Body Parts Done Right

* Part 9, Space Age Intake Meets The Basket Case

PROJECT WHITE WAGON SUPPORTERS

TL Race Cars (864) 427-5269

Fluid Power Specialties (864) 599-1118

Minton's Wrecker Service (864) 474-2581

Fulton Competition

PART SUPPLIERS

A.E.D. Motorsports Products (tubing)

Applied Racing Technologies (A.R.T)

Aeromotive Inc. (fuel system)

Autometer Guages (tech, engine gauges)

Bill Miller Engineering (rods, pistons)

Browell Bellhousings (bellhousing)

CFE Heads (cylinder heads, intake)

CFM Composites (seats)

Carson's Nut-Bolt and Tool

Comp Cams (camshaft)

Dart Engineering (Engine Block)

Flatout Gaskets (engine gaskets)

Hedman Headers (headers)

I.R.C. (wheelie bar wheels, bracketry)

Jegs Mail Order (misc.)

J&W Nova Parts (body panels and body sheetmetal)

Liberty's Transmissions (Transmission, Gears)

Matco Tools - (tools, tool box)

Mickey Thompson Tires & Wheels (front tires, slicks)

Moroso Performance (valve covers)

QA-1 (Rod Ends)

Quartermax Racing & Chassis Components (suspension, chassis components, axles)

Ram Clutches

Santhuff Shocks (front, rear shocks)

Simpson Safety - (Helmet, Firesuit)

Strange Engineering (Axles, Rearend companents)

Weld Racing (front, rear wheels)

Winberg Crankshafts (crankshaft)