PROJECT WHITE WAGON: A REAL CLUTCH PLAYER

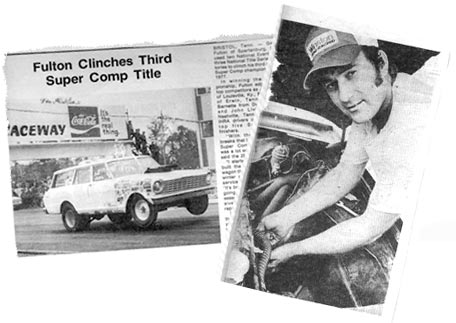

The sound of a 1970s era Modified car was very distinguishable.

A rap of the throttle elicited a high-pitched sound of horsepower much like dialing an old style rotary telephone. Just like it took seven revolutions on the old phone to make a local call, the process of bringing the stick-shifted, screaming small blocks up to peak rpm took at least three to four good raps of the throttle. At least that’s what worked well for old Fulton Competition small blocks running in the Modified and Super Stock divisions.

The melody of a heavy flywheel-inspired car is a thing of the past. Today’s modern stick shift sportsman car is all about being light, efficient and repeatable.

With that said, we’ll be implementing a double-disc, eight-inch clutch from Ram Clutches to work in conjunction with our Liberty five-speed transmission.

Pat Norcia, a proven expert in clutch technology, has assisted us in finding the right combination to propel our 3,350-pound wagon to the finish line with the same efficiency as the mountain motor Pro Stockers he works with.

The sound of a 1970s era Modified car was very distinguishable.

A rap of the throttle elicited a high-pitched sound of horsepower much like dialing an old style rotary telephone. Just like it took seven revolutions on the old phone to make a local call, the process of bringing the stick-shifted, screaming small blocks up to peak rpm took at least three to four good raps of the throttle. At least that’s what worked well for old Fulton Competition small blocks running in the Modified and Super Stock divisions.

The melody of a heavy flywheel-inspired car is a thing of the past. Today’s modern stick shift sportsman car is all about being light, efficient and repeatable.

With that said, we’ll be implementing a double-disc, eight-inch clutch from Ram Clutches to work in conjunction with our Liberty five-speed transmission.

Pat Norcia, a proven expert in clutch technology, has assisted us in finding the right combination to propel our 3,350-pound wagon to the finish line with the same efficiency as the mountain motor Pro Stockers he works with.

The first point driven home by Norcia is the difference between the clutch of today and the units of yesteryear.

“Most of the clutches in that era were Ford long style, three finger type, with a stamped steel hat and then they would use a six paddle metallic disk or they had a full circle organic disk with a sprung center in it,” explained Norcia. According to Norcia, the old school clutches were graded more on their longevity than efficiency. There were no data acquisition systems, nor did the average sportsman racer understand the importance of clutch slip or clutch slippage at the launch.

According to Norcia, the old school clutches were graded more on their longevity than efficiency. There were no data acquisition systems, nor did the average sportsman racer understand the importance of clutch slip or clutch slippage at the launch.

“Basically the cars would just spin the tires, wheel-stand and pretty much stay locked up all the way down the race track,” Norcia added. “If a guy had a clutch and it lasted 100 runs that was good because his other one only lasted 40 runs. That was the way people evaluated clutches back then.”

Norcia estimates clutch technology began taking large strides 25 years ago with the advent of on-board computers systems in Pro Stockers. The technology then trickled down into Comp and sportsman classes.

“From that point, right through today, the technology has skyrocketed, as far as knowing what's going on; the value of controlling the tire speed of the car going down the track to make a smooth run,” Norcia explained. “It's probably more boring for the spectator because it's probably not as exciting to watch.”

Long gone are the days of the heavy steel flywheels and the launches off of a clutch and line-lock. Today’s high tech car runs a lightweight flywheel and leaves with the aid of a two-step.

“They basically winged the motor up and dumped the clutch,” Norcia said smiling. “It was definitely a lot more difficult car to drive than we have today.”

Today, what we envision is a junkyard Chevy II wagon, updated to today’s modern specs and powered by essentially a Pro Stock truck engine.

a d v e r t i s e m e n t

Click to visit our sponsor's website

Norcia recommends an eight-inch clutch and admits we could use something smaller but believes the unit he has selected will provide better longevity and performance.

Norcia recommends an eight-inch clutch and admits we could use something smaller but believes the unit he has selected will provide better longevity and performance.

“You know, when you race in Super Stock you race in a wide variety of conditions,” Norcia explained. “Some of the Super Stock cars, like when you go to Indy, will be out there making runs at eight o'clock in the morning when the track is really cool and the air is really good. Then, they'll also be making runs when the track is very hot, in the early afternoon. You have to be ready for a wide array of conditions to race that category.”

To get the most use of the clutch Norcia advises we should inspect the slippage at the launch and during the course of the run.

How will we have to set this clutch up to get the most out of it?

“We want the clutch to break loose on each gear change; at the bottom of each gear going down the racetrack,” Norcia said. “Off the starting line, we’re going to use the clutch and the launch rpm depending on racetrack conditions and track temperatures. This is to optimize wheel speed and get the maximum acceleration we can get out of the car.”

One of our main challenges in building this version of Chevrolet instead of a body in white new style car is weight, and the abundance of it. Therefore we are cutting corners everywhere we can.

“Compared to the clutches that were run back in that period, when the car was originally raced, the clutch is much lighter,” Norcia said. “The weight of the clutch is moved closer to the centerline of the crankshaft which is going to make it accelerate a lot faster. Then, the surface material is much smoother and engaging and can be controlled a lot easier. Clutches back then really didn't like to be slipped very much. To make them real smooth, along with the car, you had to just go with what the clutch was going to do and the chassis was going to hold.”

Being around Pro Stock and Pro Modified pit areas, at any given time, we’ll see the clutch guy deep into the cockpit adjusting and preparing the clutch for the next run. We’ll have to do some adjustments between rounds on this car but nothing near what those guys do. However, we will have to do our homework before going to the starting line.

“Between runs you'll need to reset the ring height to the clutch and make adjustments to the base and the counterweight and then launch rpm based on the conditions of what we're going to be racing in,” Norcia explained. “And, just like in Pro Stock or Pro Mod you'll need to be looking ahead to the run you are going to make; anticipating track temperatures and atmospheric conditions so you can make adjustments for that particular run.”

And according to Norcia, it may be a Super Stocker rolling to the lanes, but it will have Pro Stock blood running through its veins.

“All that technology just trickles down to the Super Stock category,” said Norcia. “You're basically trying to achieve the same principles as you would in a Pro Stock, Pro Mod or even into a Competition Eliminator car. You're just taking it one more step down to Super Stock. Now we have a heavier car, a smaller engine with less horsepower, but we still want to achieve the same goals.”

Those goals are to run quick and efficient, and win rounds.

PART 6, FIREWALLING AND TUBING

PAST INSTALLMENTS

* Part 1, Outlining The Project

* Part 2, Getting The Car on The Jig

* Part 3, Preparing for the Four-Link

* Part 4, Preparing the Cylinder Heads

* Part 5, Project Gains A Purpose

* Part 6, Shocking the Wagon

PROJECT WHITE WAGON SUPPORTERS

TL Race Cars (864) 427-5269

Fluid Power Specialties (864) 599-1118

Minton's Wrecker Service (864) 474-2581

Fulton Competition

PART SUPPLIERS

A.E.D. Motorsports Products (tubing)

Applied Racing Technologies (A.R.T)

Aeromotive Inc. (fuel system)

Autometer Guages (tech, engine gauges)

Bill Miller Engineering (rods, pistons)

Browell Bellhousings (bellhousing)

CFE Heads (cylinder heads, intake)

CFM Composites (seats)

Carson's Nut-Bolt and Tool

Comp Cams (camshaft)

Dart Engineering (Engine Block)

Flatout Gaskets (engine gaskets)

Hedman Headers (headers)

I.R.C. (wheelie bar wheels, bracketry)

Jegs Mail Order (misc.)

J&W Nova Parts (body panels and body sheetmetal)

Liberty's Transmissions (Transmission, Gears)

Matco Tools - (tools, tool box)

Mickey Thompson Tires & Wheels (front tires, slicks)

Moroso Performance (valve covers)

QA-1 (Rod Ends)

Quartermax Racing & Chassis Components (suspension, chassis components, axles)

Ram Clutches

Santhuff Shocks (front, rear shocks)

Simpson Safety - (Helmet, Firesuit)

Strange Engineering (Axles, Rearend companents)

Weld Racing (front, rear wheels)

Winberg Crankshafts (crankshaft)