Sometimes, it seems to Trans-Dapt Performance's R & D Department that engineers intentionally  design engines to be as hard to work on, and as messy to deal with as possible. Take your oil filter, for example. Instead of the filter being mounted upright and in an easy to reach spot, it tends to be positioned in a narrow crevasse, hidden behind a bracket, and laying on it's side. With all their smarts, haven't these Detroit geniuses ever heard of gravity? If you don't have oil dripping onto the block, crossmembers, suspension boots...and yourself, when you when you unscrew the oil filter, consider yourself one of the lucky few.

design engines to be as hard to work on, and as messy to deal with as possible. Take your oil filter, for example. Instead of the filter being mounted upright and in an easy to reach spot, it tends to be positioned in a narrow crevasse, hidden behind a bracket, and laying on it's side. With all their smarts, haven't these Detroit geniuses ever heard of gravity? If you don't have oil dripping onto the block, crossmembers, suspension boots...and yourself, when you when you unscrew the oil filter, consider yourself one of the lucky few.

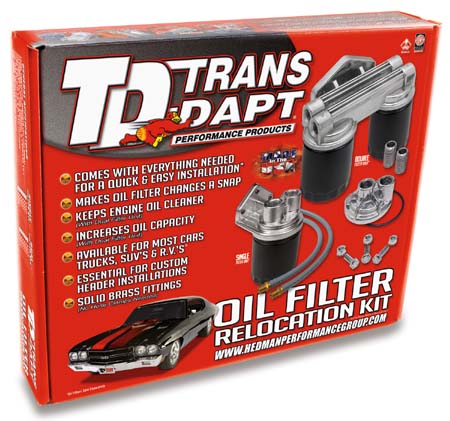

The solution to the oil filter change problem is simple, and Trans-Dapt Performance Products has the solution. Trans-Dapt is the original manufacturer of Oil Filter Relocation Kits, and they are still considered to be the best oil filter relocation system for the money. If you are not yet familiar with what they do, filter relocation kits allow you to relocate your vehicle's oil filter to virtually any spot in your engine compartment. To put one on your vehicle, just locate a sturdy spot in your engine compartment (firewall, fenderwell) and mount the horizontal oil filter base. Install the oil filter bypass adapter where the stock filter used to be, then run the two oil lines from the bypass adapter to the filter mounting base. Screw on your PH8A (or equivalent) oil filter (or filters, if you choose the dual filter model), and that's it. Next time you change the filter(s), it will be quicker, easier, and since the filters are mounted upright, there's no oil spillage.

SINGLE and DUAL filter Trans-Dapt Oil Filter Relocation Kits are available for most popular gasoline fueled cars, trucks and SUVs, including Ford, GM, Honda, Mazda, Mopar, Nissan, Toyota and VW. In addition to obvious improvement in accessibility, Trans-Dapt's Dual Oil Filter Relocation Kits also increase you engine's oil capacity by approximately a quart and doubles the filtering surface to provide a cooler, cleaner engine oil.

Each kit comes with all the brackets, hoses, fittings and mounting hardware you'll need to install it. Just supply your favorite brand oil filter, or order Trans-Dapt's #1156 compact oil filter. Trans-Dapt Kits are not for diesel, marine or competition applications. For these applications, Trans-dapt's sister company, Hamburger's Performance Products, manufactures billet aluminum oil filtration components that meet the special needs of diesel, marine and race vehicles.

To find out more about Trans-Dapt's Oil Filter Relocation Kits, visit www.tdperformance.com, email the Trans-Dapt sales staff at sales@tdperformance.com.