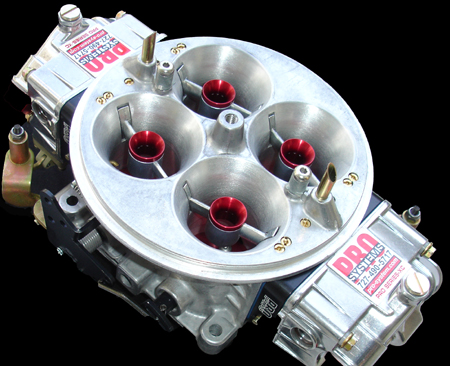

Pro Systems develops racing carburetors for many levels of competition. Late last year the Billet  metering block trend took off, but their testing never revealed the power from the addition of billet metering blocks UNTIL now.

metering block trend took off, but their testing never revealed the power from the addition of billet metering blocks UNTIL now.

According to company President Patrick James, previously tested Billet blocks were built with "End Mills" in critical areas. Using an end mill reduces machining time but creates other issues.

Since a billet block is not a casting, exact required shapes are difficult to achieve. As a result the emulsion channels and other passages were larger than required. This process also required compromises in port layout and some ports were just squared off to simplify machining. These processes saved time, but caused the carburetor to be lazier during shift recovery and launch. A condition that would only show up at the racetrack.

After extensive back to back track testing, Pro Systems determined that if you used epoxy to fill in the excess volume cut by these end mills and hand ported off some of these abrupt edges made during the machining process, they could make a billet block have the throttle response and shift recovery that the cast metering block was always famous for.

The cast metering block previously had the advantage over billet designs as by using a casting process the manufacturer could keep these areas more compact and smoother in transition. Two very important features.

Pro Systems needed a plan, a new way to machine the billet blocks to reduce these areas and remove these deep and/or squared off shapes so epoxy and hand porting were no longer required.

PROBLEM SOLVED: Pro Systems new Billet metering blocks use different machining process to minimize the emulsion area volume and eliminate the squared off shapes. This offers the increased throttle response and shift recovery that previously we were not willing to give up to enter this market. This machining process makes it a bit more difficult to build these blocks and a more expensive process, but its the right way to do a billet block.

The Pro Systems new 3 circuit billet metering block is now standard equipment on all of our Dominator carburetors.

These Pro Systems designed billet blocks are an integral part of improving the performance of our Dominator designs.

Visit www.prosystemsracing.com for a quote today. Prices start as low as $950.00