L92 Shaft Rockers from JESEL

Fri, 2007-08-03 13:16

LS

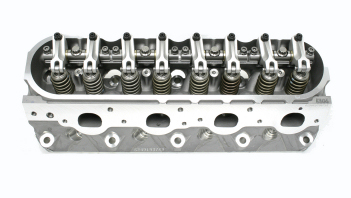

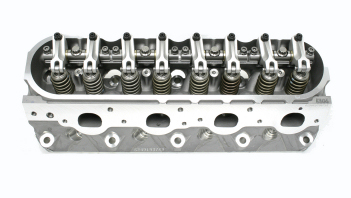

motor enthusiasts are going crazy over GMs' L92 cylinder heads that

offer huge flow numbers at an extremely reasonable price. The only

component lacking for the L92 head was a race-ready performance

valvetrain. JESEL solved that problem with a sophisticated shaft rocker

system that is capable of delivering more power due to greatly reducing

valvetrain friction, and providing rock-steady valvetrain stability at

extreme rpm.

LS

motor enthusiasts are going crazy over GMs' L92 cylinder heads that

offer huge flow numbers at an extremely reasonable price. The only

component lacking for the L92 head was a race-ready performance

valvetrain. JESEL solved that problem with a sophisticated shaft rocker

system that is capable of delivering more power due to greatly reducing

valvetrain friction, and providing rock-steady valvetrain stability at

extreme rpm.Much of the friction reduction is due to the 1.400” pivot length that reduces “scrub” between the rocker and valve tip. The rockers ride on precision needle bearings plus a .250”-wide needle bearing nose roller ensure smooth rocker action throughout the lift curve. Other standard features include JESEL’s proprietary 7000 series alloy rocker bodies CNC machined to JESEL’s exclusive Mohawk shape that provides the lightest and stiffest rocker possible. The rocker bodies also featured profiled tail sections for valve cover clearance and are shotpeened for added strength.

There is a choice of rocker ratios from 1.65-1.90, and tool steel pushrod cup adjusters are also standard. Optional ball adjusters are available for reduced friction and to add even more strength to the rocker body (another JESEL innovation). ARP hardware anchors the one-piece billet steel stands and centerless-ground shaft assemblies.

Installation is a simple bolt-on operation with no cylinder head machining required. However, taller valve covers or valve cover spacers are required for adequate clearance. For more information please contact JESEL at 1985 Cedarbridge Ave., Lakewood, NJ 08701. Phone 732-901-1800. Fax 732-901-6777. Or visit us on the web at www.jesel.com

LS motor enthusiasts are going crazy over GMs' L92 cylinder heads that offer huge flow numbers at an extremely reasonable price. The only component lacking for the L92 head was a race-ready performance valvetrain. JESEL solved that problem with a sophisticated shaft rocker system that is capable of delivering more power due to greatly reducing valvetrain friction, and providing rock-steady valvetrain stability at extreme rpm.

LS motor enthusiasts are going crazy over GMs' L92 cylinder heads that offer huge flow numbers at an extremely reasonable price. The only component lacking for the L92 head was a race-ready performance valvetrain. JESEL solved that problem with a sophisticated shaft rocker system that is capable of delivering more power due to greatly reducing valvetrain friction, and providing rock-steady valvetrain stability at extreme rpm.Much of the friction reduction is due to the 1.400” pivot length that reduces “scrub” between the rocker and valve tip. The rockers ride on precision needle bearings plus a .250”-wide needle bearing nose roller ensure smooth rocker action throughout the lift curve. Other standard features include JESEL’s proprietary 7000 series alloy rocker bodies CNC machined to JESEL’s exclusive Mohawk shape that provides the lightest and stiffest rocker possible. The rocker bodies also featured profiled tail sections for valve cover clearance and are shotpeened for added strength.

There is a choice of rocker ratios from 1.65-1.90, and tool steel pushrod cup adjusters are also standard. Optional ball adjusters are available for reduced friction and to add even more strength to the rocker body (another JESEL innovation). ARP hardware anchors the one-piece billet steel stands and centerless-ground shaft assemblies.

Installation is a simple bolt-on operation with no cylinder head machining required. However, taller valve covers or valve cover spacers are required for adequate clearance. For more information please contact JESEL at 1985 Cedarbridge Ave., Lakewood, NJ 08701. Phone 732-901-1800. Fax 732-901-6777. Or visit us on the web at www.jesel.com

Categories: