COMP Cams expands Aluminum Shaft Rocker Line Up

Thu, 2007-07-19 07:22

Nine applications introduced to fit popular Brodix, Dart, Edelbrock & RHS cylinder heads

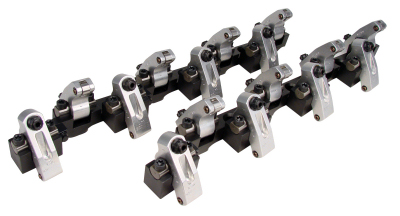

Nine applications introduced to fit popular Brodix, Dart, Edelbrock & RHS cylinder heads COMP Cams® Aluminum Shaft Rocker Arm Systems are a popular choice for professional engine builders who desire increased valve train and cylinder head stability for improved performance and overall durability in all-out race engine applications. COMP Cams® announces the expansion of their shaft rocker arm system line to include nine new applications, including GM, Ford and Chrysler engines. Constructed from 2024 aluminum, these high-tech rockers ride on an 8620 hardened steel shaft and feature an efficiently designed oiling system that ensures consistent flow. Rocker arm ratios for these assemblies range from 1.5 through 1.7:1, depending on cylinder head application.

The nine new COMP Cams® shaft rocker arm assemblies include the Pro TopLine/RHS™ Pro Action™ 1.5/1.5:1 ratio iron and aluminum cylinder heads, Big Block Chevrolet Brodix Big Brodie and 18-degree Big Brodie heads, Small Block Ford Windsor 302/351W OEM heads, three different Small and Big Block Chrysler heads and the Pontiac Edelbrock 1.5:1 cylinder heads. Installation of the COMP Cams® shaft rocker system is generally a bolt-on process completed without machining; however verification of that fact should be completed when purchasing these assemblies as application requirements do differ slightly.

For more information about ordering COMP Cams® shaft rocker arm assemblies for your engine or any other COMP Cams® product, call us at 1-800-999-0853, or visit us online at www.compcams.com

Nine applications introduced to fit popular Brodix, Dart, Edelbrock & RHS cylinder heads

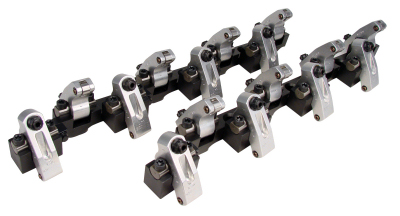

Nine applications introduced to fit popular Brodix, Dart, Edelbrock & RHS cylinder heads COMP Cams® Aluminum Shaft Rocker Arm Systems are a popular choice for professional engine builders who desire increased valve train and cylinder head stability for improved performance and overall durability in all-out race engine applications. COMP Cams® announces the expansion of their shaft rocker arm system line to include nine new applications, including GM, Ford and Chrysler engines. Constructed from 2024 aluminum, these high-tech rockers ride on an 8620 hardened steel shaft and feature an efficiently designed oiling system that ensures consistent flow. Rocker arm ratios for these assemblies range from 1.5 through 1.7:1, depending on cylinder head application.

The nine new COMP Cams® shaft rocker arm assemblies include the Pro TopLine/RHS™ Pro Action™ 1.5/1.5:1 ratio iron and aluminum cylinder heads, Big Block Chevrolet Brodix Big Brodie and 18-degree Big Brodie heads, Small Block Ford Windsor 302/351W OEM heads, three different Small and Big Block Chrysler heads and the Pontiac Edelbrock 1.5:1 cylinder heads. Installation of the COMP Cams® shaft rocker system is generally a bolt-on process completed without machining; however verification of that fact should be completed when purchasing these assemblies as application requirements do differ slightly.

For more information about ordering COMP Cams® shaft rocker arm assemblies for your engine or any other COMP Cams® product, call us at 1-800-999-0853, or visit us online at www.compcams.com

Categories: